Electric high temperature and high pressure gate valve

Technical Parameters

Product model: Z960Y

Nominal diameter: DN100~350mm

Nominal pressure: PN16.0-32.0MPa

Main material: carbon steel, alloy steel

Applicable temperature: -29℃~+600℃

Drive mode: electric

Applicable medium: water, oil, steam, acidic medium, etc.

Product Description

Electric high temperature and high pressure gate valve is suitable for the nominal pressure PN16.0-32.0MPa, the working temperature ≤ 540 ℃ (the working temperature of P57170V is 570 ℃), on the pipeline of various systems of petroleum, chemical, hydraulic and thermal power plants, cutting off or connecting the pipe road medium.

Product Features

1. The middle cavity of the valve adopts a pressure self-tightening sealing structure, which has good sealing performance.

2. The sealing surfaces of the valve disc and valve seat are made of cobalt-based cemented carbide, which is wear-resistant, high-temperature resistant, has good scratch resistance and long service life.

3. The valve stem is treated with anti-corrosion nitriding, which has good corrosion resistance and scratch resistance.

4. High temperature creep resistance design.

5. The depth of the bonnet stuffing box is reasonable, the packing is added with corrosion inhibitor, and the sealing is reliable.

6. The valve has an upper sealing structure to ensure that the valve stem will not leak when the valve is opened and operated.

7. The structure of the opening and closing parts can be designed into different forms such as single board, double board, parallel double board and so on according to user requirements

Main performance specifications

|

Model PN(MPa) |

Test pressure(MPa) |

Work pressure(MPa) |

Operating temperature(℃) |

Applicable media |

||

|

Strength test |

Seal test / upper seal test |

|||||

|

Z960Y-250 |

25 |

37.5 |

27.5 |

- |

≤425 |

steam |

|

Z960Y-320 |

32 |

48.0 |

36.0 |

- |

≤425 |

|

|

Z960Y-P54100 |

- |

30.0 |

22.0 |

P5410 |

≤540 |

steam |

|

Z960Y-P54170 |

- |

48.0 |

36.0 |

P5417 |

≤540 |

|

Material of main parts

|

Part Name |

Material |

||

|

Body |

WCB |

WC6 |

WC9 |

|

Plate |

WCB |

WC6 |

WC9 |

|

Cap |

25 |

12Cr1Mo1VA |

|

|

Stem |

1Cr17Ni2 |

20Cr1Mo1VA |

|

|

Seat |

25 |

12Cr1Mo1VA |

|

|

Seal ring |

S mild steel (reinforced flexible graphite) |

S mild steel |

F mild steel |

|

Packing |

Reinforced flexible graphite |

||

|

Bracket |

WCB |

WCB&WC6 |

|

|

Stem Nut |

45(ZCuZn25A16Fe3Mn3) |

||

|

Four open loops |

1Cr13 |

20Cr1MoVA |

- |

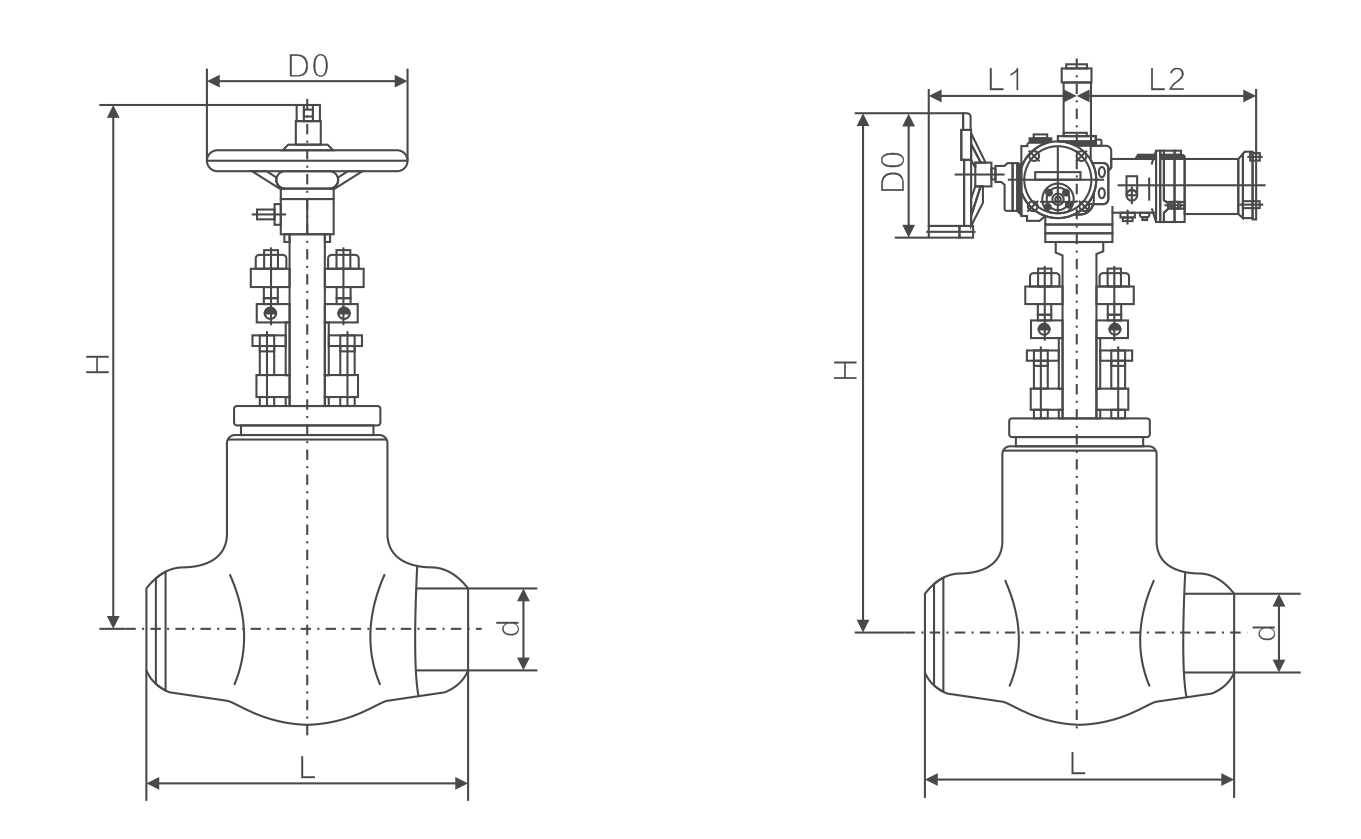

Main external connection dimensions

| DN | Main external connection dimensions | Electric device | WT(kg) | ||||

| d | L | H | L1 | L2 | |||

| Z960Y-250 | |||||||

| 100 | 84 | 406 | 1164 | 437 | 277 | DZW45 | 234 |

| 125 | 100 | 483 | 1402 | 437 | 277 | DZW60 | 343 |

| 175 | 158 | 711 | 1650 | 554 | 309 | DZW180 | 638 |

| 225 | 200 | 864 | 1650 | 554 | 309 | DZW180 | 654 |

| 300 | 280 | 1067 | 2106 | 764 | 398 | DZW350 | 1973 |

| Z960Y-320 | |||||||

| 100 | 96 | 533 | 1236 | 437 | 277 | DZW60 | 291 |

| 125 | 118 | 610 | 1302 | 437 | 277 | DZW60 | 315 |

| 150 | 148 | 762 | 1403 | 526 | 283 | DZW90 | 672 |

| 175 | 148 | 762 | 1650 | 554 | 309 | DZW180 | 684 |

| 225 | 222 | 1041 | 1650 | 554 | 309 | DZW180 | 696 |

| Z960Y-P54100V | |||||||

| 175 | 148 | 762 | 1650 | 554 | 309 | DZW180 | 683 |

| 225 | 222 | 1041 | 1650 | 554 | 309 | DZW180 | 704 |

| 250 | 222 | 1041 | 1795 | 554 | 309 | DZW180 | 1214 |

| 300 | 294 | 1245 | 2080 | 554 | 309 | DZW250 | 2125 |

| Z960Y-P54170V | |||||||

| 125 | 98 | 630 | 1230 | 437 | 277 | DZW60 | 312 |

| 225 | 186 | 1060 | 1680 | 554 | 309 | DZW180 | 1401 |

| 300 | 278 | 1397 | 2265 | 764 | - | DZW500 | 2834 |

| 325 | 310 | 1448 | 2265 | 690 | 398 | DZW500 | 2632 |

| 350 | 338 | 1550 | 2536 | 715 | - | DZWC-4 | - |